Geothermal Heat Pumps Commercial and Residential

Huge Energy Savings with Great Tax Benefits

Geothermal Heat Pump Opportunities

Geothermal heat pumps offer an immense opportunity to see immediate reductions in both heating and cooling costs for any building by harnessing the energy stored in the earth. Over time, a geothermal heat pump will pay for itself in energy savings, allowing companies to serve both their environmental interests and their bottom line simultaneously. New incentives make the payback period even shorter, meaning that a company can not only have the system pay for itself, but begin to profit from energy savings quicker as well. In October 2008, the U.S. Congress passed The Emergency Economic Stabilization Act of 2008 (H.R. 1424), extending the Investment Tax Credit (ITC) to include geothermal heat pumps installed after October 3, 2008 until 2016. A 10% credit of the installed costs against a company's taxes is provided for a geothermal heat pump. If the credit exceeds the tax liability, a loss can be carried forward for one year.

Click Here available Tax Credits for your New Geothermal Heat Pump

Geothermal heat pumps offer an immense opportunity to see immediate reductions in both heating and cooling costs for any building by harnessing the energy stored in the earth. Over time, a geothermal heat pump will pay for itself in energy savings, allowing companies to serve both their environmental interests and their bottom line simultaneously. New incentives make the payback period even shorter, meaning that a company can not only have the system pay for itself, but begin to profit from energy savings quicker as well. In October 2008, the U.S. Congress passed The Emergency Economic Stabilization Act of 2008 (H.R. 1424), extending the Investment Tax Credit (ITC) to include geothermal heat pumps installed after October 3, 2008 until 2016. A 10% credit of the installed costs against a company's taxes is provided for a geothermal heat pump. If the credit exceeds the tax liability, a loss can be carried forward for one year.

Click Here available Tax Credits for your New Geothermal Heat Pump

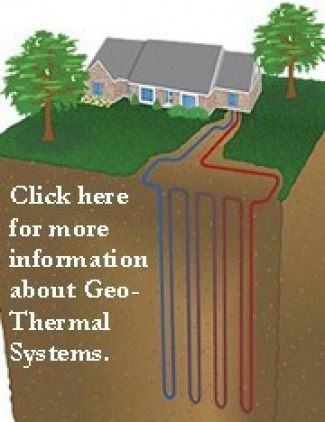

System Designs and Processes Commercial

The earth has a tremendous capacity for storing thermal energy which can be utilized to heat or cool a building. Although the initial cost of a geothermal application may be higher, if one considers the life cycle savings in energy and the reduced maintenance costs, then geothermal is the smartest decision for your project. Geothermal systems are especially recommended in areas that have significant heating and cooling loads. In areas that are either cooling or heating dominant our hybrid systems could be the perfect solution for your needs. Using a cooling tower in conjunction with a ground loop in areas that have a cooling dominant load reduces the cost of the loop field with only a small impact on the efficiency of the system. Conversely, in areas that are heating dominant, the addition of a boiler to a geothermal loop reduces the loop field cost with a minimal effect on the efficiency of the system.

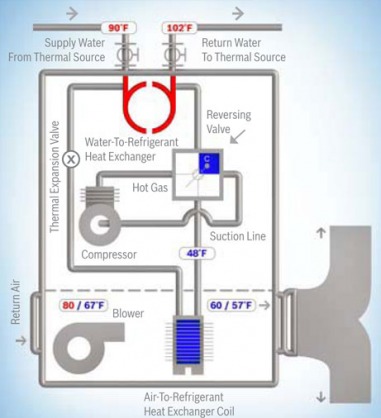

COOLING MODE

In the COOLING mode

The refrigerant, a hot gas, is pumped from the compressor to the water-to-refrigerant heat exchanger via the reversing valve. Water, generally with an anti freeze, following through the water-to-refrigerant heat exchanger removes heat and the hot gas condenses into a liquid. This liquid then flows through a metering device to the air-to-refrigerant heat exchanger coil. In evaporating into a gas, the liquid absorbs heat and cools and dehumidifies the air that passes over the coil surface. The cooling cycle is completed when the surface. The cooling cycle is completed when the reversing valve and back to the suction side of the compressor.

The refrigerant, a hot gas, is pumped from the compressor to the water-to-refrigerant heat exchanger via the reversing valve. Water, generally with an anti freeze, following through the water-to-refrigerant heat exchanger removes heat and the hot gas condenses into a liquid. This liquid then flows through a metering device to the air-to-refrigerant heat exchanger coil. In evaporating into a gas, the liquid absorbs heat and cools and dehumidifies the air that passes over the coil surface. The cooling cycle is completed when the surface. The cooling cycle is completed when the reversing valve and back to the suction side of the compressor.

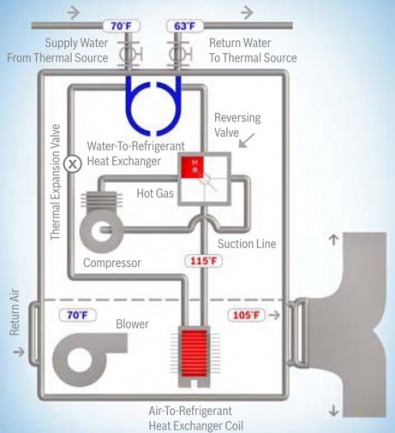

HEATING MODE

During the HEATING mode

The refrigerant, a hot gas, is pumped from the compressor to the air-to-refrigerant heat exchanger coil via the reversing valve. In the air-to-refrigerant heat exchanger coil, the heat is removed by the air that passes over the coil surface, and the hot gas condenses into a liquid. The air is circulated to the space and provides heating for the building. The refrigerant liquid then flows through a metering system to the water-to-refrigerant heat exchanger. While it evaporates into a gas, the liquid absorbs heat and cools the water. The heating cycle is completed when the refrigerant flows as a low pressure gas through the reversing valve and back to the suction side of the compressor.

The refrigerant, a hot gas, is pumped from the compressor to the air-to-refrigerant heat exchanger coil via the reversing valve. In the air-to-refrigerant heat exchanger coil, the heat is removed by the air that passes over the coil surface, and the hot gas condenses into a liquid. The air is circulated to the space and provides heating for the building. The refrigerant liquid then flows through a metering system to the water-to-refrigerant heat exchanger. While it evaporates into a gas, the liquid absorbs heat and cools the water. The heating cycle is completed when the refrigerant flows as a low pressure gas through the reversing valve and back to the suction side of the compressor.

Click Picture Below for all Earth Coupling Options

Residential Design